PC-Woody® is a two part epoxy paste that is excellent for filling cavities in wood. Make permanent repairs without shrinking, cracking or popping out of exterior wood. Sand, drill, nail, prime and paint or stain. Bonding filler for replacement wood. Not brittle. Easy 1:1 mix ratio (see: How to Mix PC-Woody).

When measuring equal parts “A” and “B” we generally recommend eyeballing the amounts (see: How to Measure PC-Woody) but if more precise measurements are desired, based on an average net weight for each size unit we have:

Woody 106 grams A to 100 grams B

Here are just a few specific uses (there are hundreds of other uses):

ADVISEMENT: Staining PC-Woody is recommended using solid stain. Using semi-transparent stain is possible but results will vary depending on the stain. Transparent stains that contain only dye will produce disappointing results. Coloring PC-Woody with tints or dry pigments is sometimes helpful. Stain markers and pencils can add grain.

PC-Woody® | 1.5 oz.

PC-Woody® | 6 oz.

PC-Woody® | 12 oz.

PC-Woody® | 48 oz.

PC-Woody® | 96 oz.

PC-Woody® | 10 gallon

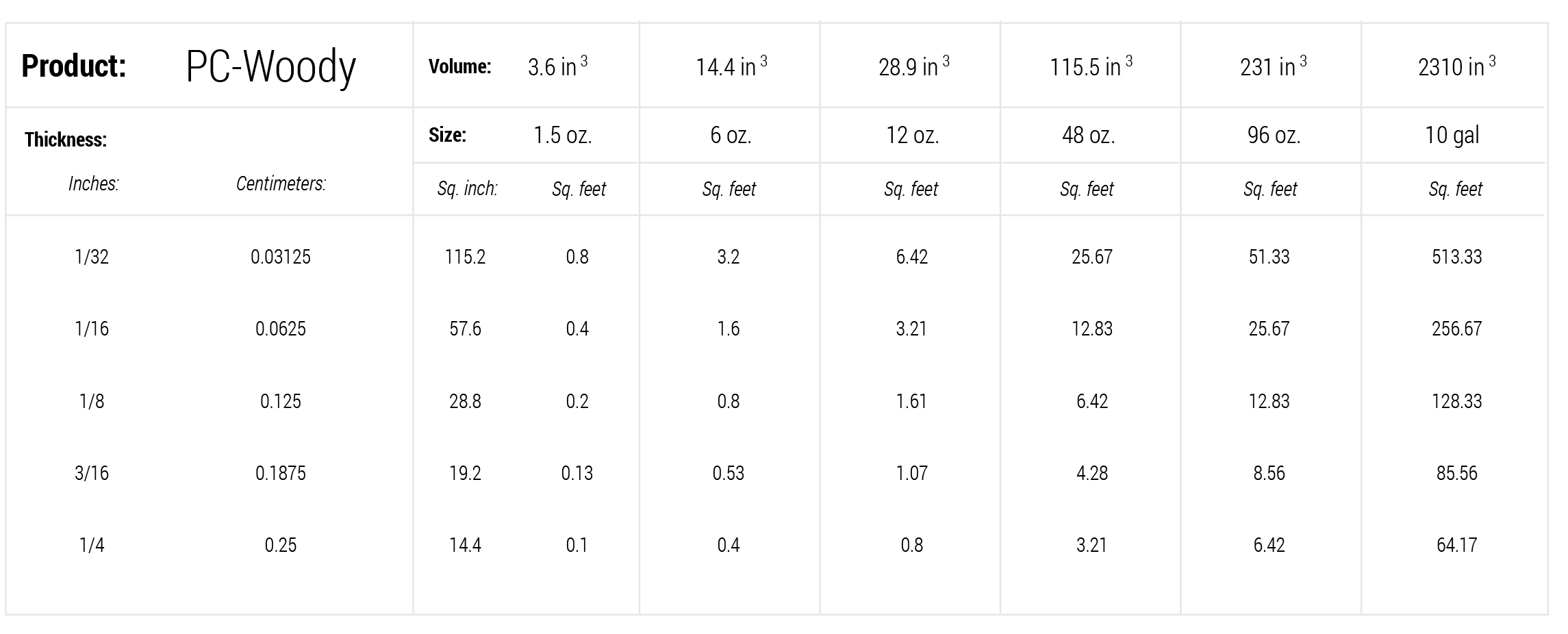

How much coverage? Minimum suggested bond line thickness is 1/32 inch for two flat surfaces. Minimum suggested bond line for two uneven or rough surfaces is 1/8 inch.

QUANTITIES: Package sizes are listed in total quantities of weight, both English and metric units. PC-Woody is a two-part epoxy (A + B) that has an equal volume mix ratio. It is sold by total weight (A + B) not volume. A rough estimate how many ounces of PC-Woody are needed to fill a large cavitiy can be calculated by dividing cubic inches by 2 to get the approximate number of ounces.

How to prepare a surface for bonding with PC-Woody®

Remove loose paint, wood fibers and debris with stiff brush, sandpaper or scraper. Dust, dirt, oil and grime can be removed with damp paper towel and denatured alcohol (ethanol), acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner. Soft, decayed or insect damaged wood can be hardened with PC-Petrifier® or PC-Rot Terminator®.

How to clean-up after PC-Woody® application

Clean up mixed epoxy before it cures with paper towels and solvent. Denatured alcohol (ethanol), acetone, rubbing alcohol (isopropyl alcohol) or lacquer thinner are suitable solvents for removing uncured epoxy. Cured PC-Woody can be removed with paint stripper or remover.

Is PC-Woody® stainable? Tint-able?

PC-Woody® contains real wood and will accept solid stain after sanding. However, staining with semi-transparent or transparent stains rarely matches the surrounding wood. It is possible to tint PC-Woody® but matching colors is difficult with pigments or universal color tints. When tinting, darker is less obvious than lighter.

Should PC-Woody® be applied in layers? How thick can PC-Woody® be applied?

PC-Woody® can be applied in layers but it is not necessary to do so. After part A and B have been mixed it can be applied in any thickness. Be advised that filling deep cavities on vertical surfaces should be done in layers to avoid slumping. It is possible to block slumping using a form covered with wax paper or polyethylene film. PC-Woody® cures through with or without exposure to air.

Will PC-Woody® shrink or pop out?

PC-Woody® does not contain any solvents to evaporate and cause shrinkage but be advised that it may be necessary to apply a second thin layer over thicker sections due to post reaction cooling effect. PC-Woody® is unlikely to pop out because it is slightly flexible, permitting it to expand and contract with the wood.

PC-Woody® is sandable but can it be carved or filed? Can a wood-turner put it on the lathe?

PC-Woody® has been carved. Sculptors have used it successfully to fill gouges and missing wood. PC-Woody® can be turned on a lathe but it will do so differently than wood. Wear a respirator and ventilate mechanically.

What grit sandpaper is good for sanding PC-Woody®? Can a mechanical sander be used?

80 grit sandpaper work nicely to reduce cured PC-Woody®. Fine sandpaper such as 120, 150 and 180 can also be used. Mechanical sanders work best after 48 hours. Wear a respirator and ventilate mechanically.

Is the PC-Woody® suitable for structural repairs?

Consult an engineer for critical structural applications. PC-Woody® is suitable when used in conjunction with new wood or steel supports.

After PC-Woody® cures, is it possible to turn a screw or hammer a nail into it?

PC-Woody® will accept various sized screws and nails. It is best to drill a small pilot hole first.

Does cooler weather affect the way PC-Woody® cures?

PC-Woody® will require additional time to cure at cooler temperatures. Temperatures below 50° F may require a heat source such as a heat lamp to accelerate the curing. It is not recommended to apply PC-Woody® at temperatures at or below freezing. Very cold temperatures will pause the reaction until temperatures rise.

How soon after application of the PC-Rot Terminator® can the PC-Woody® be applied?

It is best to wait until PC-Rot Terminator® has fully soaked into the wood before applying PC-Woody® but it is not necessary to wait until PC-Rot Terminator® has fully cured.

The PC-Woody® part B is not drying.

PC-Woody® part B must be mixed with PC-Woody® part A in equal volumes. The PC-Woody® part B will not cure by itself and must be removed and mixed properly. It is not recommended to mix PC-Woody® in teaspoon size increments or smaller, simply because of the likelihood of an ‘off-ratio’ mix. Be sure to mix equal parts of Resin to Hardener 1:1.

Is it ok to mix PC-Woody with stain to make it darker?

Stains will often settle. This sediment can be used to tint the PC-Woody® in some circumstances. Better to use dry pigment powder to achieve darker shades.

The PC-Woody® part B is dark and has a little bit of oil on the surface.

As PC-Woody® part B ages it can become darker and separate. Stir any liquid back into the PC-Woody® before using.